Thermoset Compounding and Injection Moulding

The production of complex components with a high thermal stability and simultaneously the possibility to attain high filling rates make injection molding thermosets advantageous in various applications. Functionalized polymers (thermal conductivity, magnetism, mechanics) for high-temperature applications have gained increasing interest due to the increased requirements in power electronics but also by increasing the functional density in assemblies such as the car engine compartment. Due to the great potential for filler content, the functionalization (eg. thermal conductivity, magnetic) of thermosets can easily be actualized and the property profile can be tailored to the different requirements very well.

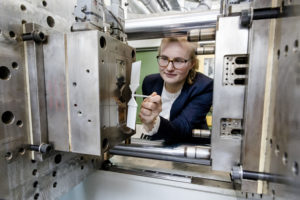

Research at LKT mainly deals with the systematic investigation of the processing parameters while compounding functionalized thermoset molding compounds, and of fundamental factors during injection molding processing. Furthermore, research is being conducted on methods for the preparation of dense media systems by molding with thermosetting materials.

Additionally, with a specialized tool setup, we have the capability to not only monitor temperature and pressure along the flow path extensively but also determine the inline viscosity during the component’s production. In particular, viscosity changes during mold filling and curing are recorded to gain a better understanding of the material’s characteristics in real time. This innovative sensor integration enables more precise process monitoring and opens up new possibilities for optimizing the injection molding process for high-performance thermoset applications.

Dr.-Ing. Uta Rösel

Institute of Polymer Technology

Processing (Head of Department)

- Phone number: +49913185-71002

- Email: uta.ur.roesel@fau.de