Joining Technology / Welding

If thermoplastic components can not be produced in a single manufacturing step due to their complexity, the use of joining technologies is then required. Welding involves the benefits of a cohesive and medium-tight connection, which allows for high load transfers without the use of additional materials. Vibration welding of thermoplastic materials is characterized by short cycle times, energy efficiency, its suitability for large parts and good reproducibility. The advantage of infrared welding is that heating the joining surfaces takes place without any contact. Thus, welding plastics with higher temperature resistances in a two-step process without any adhesion of the resulting melt to a heating element is possible.

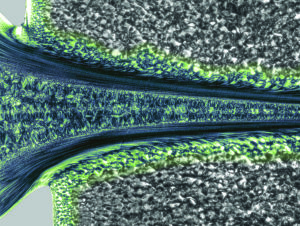

In addition to the infrared welding infrared emitters are also successfully used for preheating or preplastification in combination with vibration welding. With the combination of these two welding processes the joint surfaces are melted with an infrared emitter prior to the actual vibration welding process. After a low melt layer thickness of 0.1 to 0.2 mm has been established, the infrared emitter is removed and the vibration process is started. Because the vibration process starts in the melt (no solid friction), there is no longer the risk of particle release.

Research at LKT deals with the study of structure property relations in the joint zone, the development of strategies for online quality assurance, and various possibilities for producing mixed material joints, such as welding thermoplastics of dissimilar types (eg. standard thermoplastics with high-temperature thermoplastics), FRP-metal joints as well as joining techniques for thermosets.

Transregio 285

- Method development for mechanical joinability in versatile process chains

- Homepage: TRR 285

- Research at LKT in C01: Mechanical joining without auxiliary elements using load- and material-adapted pin structures

- Contact person at LKT: Jan Gavelek, M.Sc.

Dr.-Ing. Uta Rösel

Institute of Polymer Technology

Processing (Head of Department)

- Phone number: +49913185-71002

- Email: uta.ur.roesel@fau.de