Thin-Wall and Micro-Technology

| Influence of the Process Temperature on Morphology |

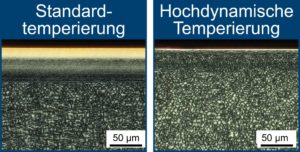

Due to the demand for the miniaturization of high-performance parts as well as the reduction of materials and costs, today’s injection moulded thin-wall and micro parts have established a notable and necessary technical standard. Nevertheless, technical thermoplastic’s potential has not yet been fully utilized. Because of the geometric factors, the material undergoes a short cooling during the manufacturing process. The influence on the inner structure is reflected in an altered application behavior.

The Institute of Polymer Technology systematically analyses the cause-effect relationship of processing, the formation of inner structure and the resulting properties in use, e.g. for applications in tribological systems. The research is mainly directed towards the optimization of processing and usage behavior with the development and investigation of novel processing techniques, e.g. low heat-conducted mould materials or dynamic tempering of the cavity. Processing variants like expansion injection moulding are also included. Furthermore, dimensional and processing-dependent influences on the long-term behavior (ageing) of these parts are further characterized. Dimensional-adapted testing technologies are simultaneously enhanced and optimized for a precise part characterization.

Research on the extension of processing techniques into micro technology is of great importance at the institute. Current work is focused on micro-thermoforming of thermoplastic foils and their integration into the injection moulding process to establish multifunctional, thin-walled micro-structured parts.

Dr.-Ing. Uta Rösel

Institute of Polymer Technology

Processing (Head of Department)

- Phone number: +49913185-71002

- Email: uta.ur.roesel@fau.de