Thermoforming

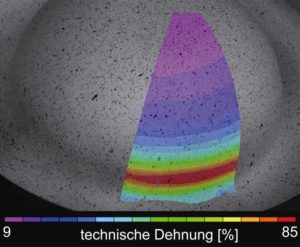

| Technical Strain caused by Forming Process |

Thermoforming is a profitable processing technology for packaging, automotive parts and consumer or sports goods. Thermoforming allows for the fabrication of large-area parts with great as well as very little wall thicknesses. Furthermore, investment costs for machinery and tools can be relatively low, because only single-sided moulds are needed for some process variants. Moreover multi-layered, decorated or printed sheets can be thermoformed. On the other hand, the variety of plastic materials available for thermoforming is limited. Thermal and rheological requirements for thermoforming are quite high and are often fulfilled only by amorphous thermoplastics.

Research at the Institute of Polymer Technology focusses, amongst others, on material, process and part characterization as well as on specific material modification to improve the thermoformability of polymers, e.g. polyamides, which have not been available for thermoforming up to now. Thereby, well-established materials, processes and applications shall be optimized and new fields of application for thermoforming and thermoformed parts shall be developed.

Dr.-Ing. Uta Rösel

Institute of Polymer Technology

Processing (Head of Department)

- Phone number: +49913185-71002

- Email: uta.ur.roesel@fau.de